Screw Thread Protection in Engineered Components

Screw thread protection is essential in engineered components, especially in high-integrity applications across automotive, nuclear, and defence sectors. At Hague Fasteners, we understand that even minor thread damage can compromise performance, safety, and reliability. That’s why we’ve built our reputation on precision, quality, and proactive protection methods.

Why Screw Thread Protection Matters in Critical Applications

Screw thread damage is one of the most common causes of component failure in the fastener manufacturing sector. Since 1971, Hague Fasteners has implemented rigorous quality systems to prevent this risk. Learn more about our screw thread protection methods.

- Premature Failure: Damaged threads can cause assemblies to loosen or disconnect. In high-stakes environments, this can lead to system-wide failure.

- Increased Maintenance Costs: Compromised threads often require early replacement or repair, resulting in downtime and higher operational costs.

- Reduced Efficiency: Loose connections may cause vibration, leading to mechanical degradation and increased energy consumption over time.

How Hague Fasteners Protects Precision Threads

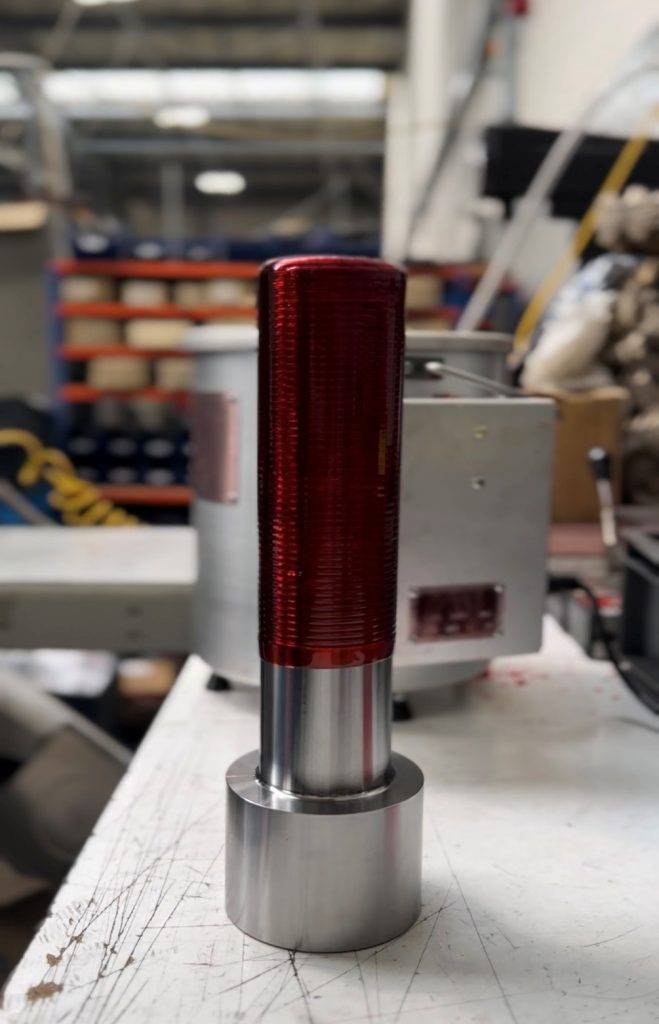

We take screw thread protection seriously. One of our most effective methods is wax dipping—a process that coats components in a protective wax layer after machining. This is done by hand, as no two orders are ever the same.

This barrier shields threads from knocks, moisture, and contaminants during storage, shipping, and handling. Moreover, it offers several key advantages:

- Prevents physical damage during handling

- Provides up to 10 years of rust prevention

- Outperforms traditional mesh sleeves in durability and coverage

As a result, our components arrive in perfect condition—ready to perform with the precision and reliability our clients expect.

Built-In Protection for Built-To-Last Components

As a third-generation British manufacturer, we understand that quality doesn’t end at the production line. It extends to how components are handled, stored, and delivered.

That’s why we go the extra mile to protect every thread, every time. Whether you’re sourcing fasteners for high-pressure systems or bespoke engineered parts, screw thread protection matters—and we’re here to ensure it’s never compromised.

📽️ Follow us on social media to see our viral bolt dipping videos in action and learn more about our commitment to quality.

📞 Ready to discuss your next project?

Get in touch with our team to learn how we can support your critical applications.